The wind turbine consists of a nose, a rotor, a tail wing and a blade. Every part is important. In the manufacturing process of wind power equipment blades, isolation film, vacuum bag and other products are needed. Our company specializes in the production of products suitable for wind power industry.

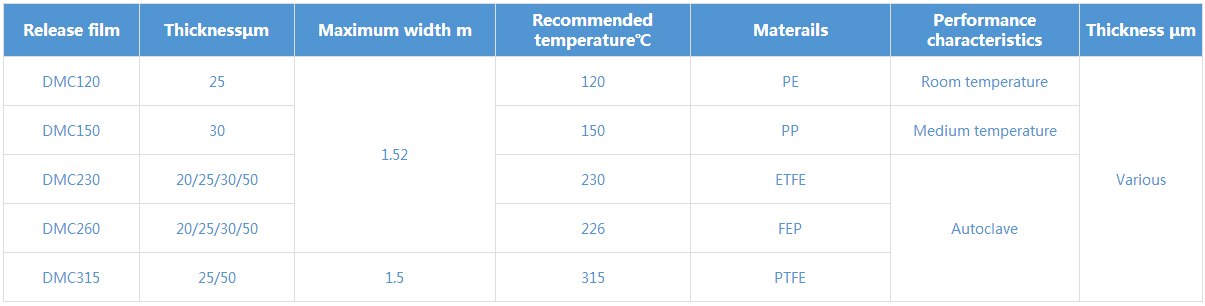

1.Vacuum bag Vacuum pouring process is a kind of process technology which uses vacuum pressure to make moulding. The concept is to directly lay fiber reinforced materials and foam materials on the molds, then close the positive and negative modes (Yin and Yang modes) or wrap them in a vacuum bag, seal the mould, and then use the vacuum pump to pump to the negative pressure state. Finally, the resin is spread through the whole system of the rubber hose, and the layer is soaked through the components. |  |

|

●1.Health Care and Safety Guarantee advantages: Reducing more than ●2.Production advantages: lower cost of consumables, faster flow rate, ●3.Quality and performance advantages: Fiber reinforced fabric content |

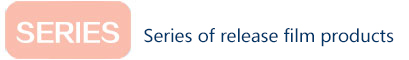

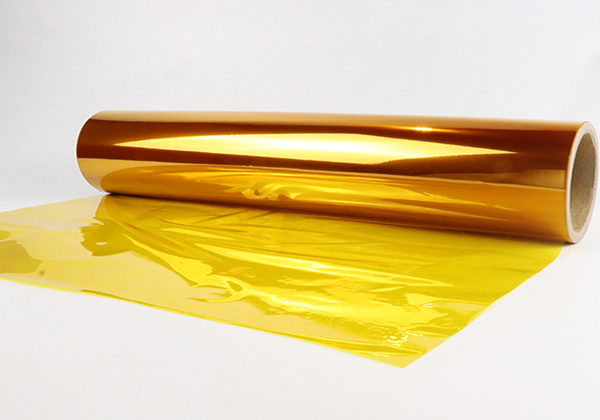

DMC can provide the following series of isolation film products . |  |

|

|